You are here: Home > British Military > Ordnance

Projectiles and Rifling > Rifling Machines

In small arms the projectile of lead is so soft, small, and mouldable, that no serious difficulties are found in causing it to adapt itself to the spirals of the barrel, so as perfectly to take the spin without injury to the spirals; but the case is widely different in great guns. The mass of the projectile must be of rigid material, of iron or steel; either, then, some tertium quid of soft and mouldalde material, like lead, must be adapted to its exterior, that shall at the moment of projection adapt itself to the spirals also, or workmanship the most exquisite and precise must be employed to produce in each shot a rigid piston, perfectly fitting the spirals. Armstrong adopts the former, Whitworth the latter alternative. Lancaster might employ either the one or the other, but did employ (though imperfectly carried out) the second. Simple as are these conditions, when they are brought further into contact with those of continued and actual service, they are found to involve difficulties that have taxed the ingenuity of many minds, and have produced a perfect encyclopaedia of plans for the construction of shot and spirals, none of which can be said as yet to be admittedly perfect.

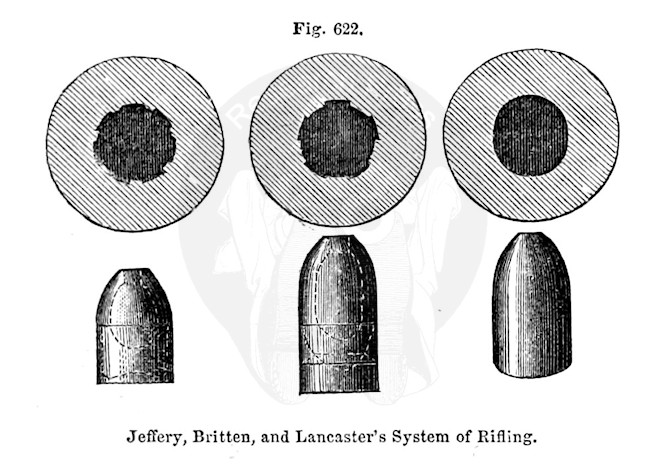

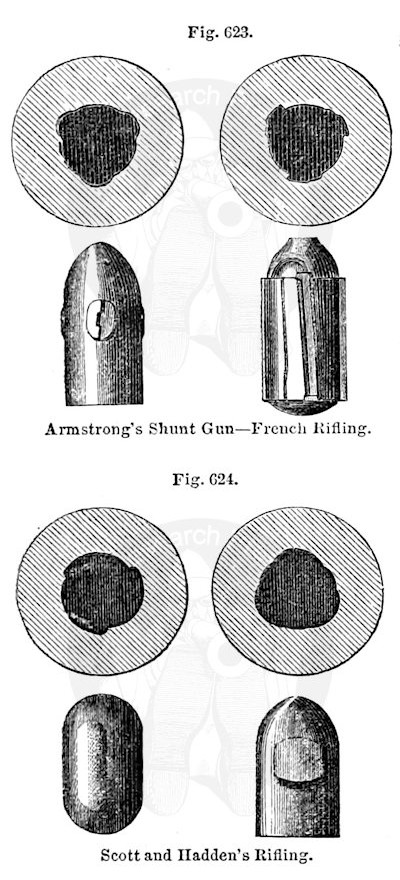

One of the two great classes of rifled cannon shot, viz., that of hard and soft metal combined, is again subdivisible, into those in which the shot is already by formation nearly adapted to fit the spirals of the gun, and is deformed by the explosion only to such an extent, as shall enable the soft metal quite to fill the windage, &c.; to this belong the French, Italian, and Spanish projectiles, and those of Britten, Jeffery, and the Armstrong shunt gun, with others; and those in which the soft metal, by formation a cylinder or other form larger than the rifled chase, is at the moment of explosion deformed to the full extent of the rifling, and takes the form of the spirals by being forced through them, as wire is passed through the draw plate.

To this latter class the Armstrong projectiles (except those of the shunt gun) belong. These involve breech-loading cannon as a matter of necessity, because by no other means can the projectile, larger in diameter than the chase of the gun, be introduced; and also demand fine spiral groovings, such as those which (called formerly in small arms hair rifling) in the shape of the teeth of a ratchet wheel, characterise the Armstrong guns.

In Figs. 622, 623, 624, are given seven of the more remarkable of the forms of rifle spirals and projectiles that are before the public in this country, being those which in August and September, 1861, were submitted to certain competitive trials at Shoeburyness as to their shooting, and since that to trials as to endurance of the guns, at Woolwich, which as respects some of them are not even yet concluded. Of these, Lancaster’s, Hadden’s, and Scott’s projectiles are wholly of hard material, and amongst these in class would be placed Whitworth’s shot, which is in section where it fits the chase a hexagon, with the angles taken off. The projectiles of Armstrong’s shunt gun, and of the French “canon rayé” have the projections to fit the spirals, partly of hard and partly of soft metal, while Britten’s and Jeffery’s are so coated with soft metal (lead, or an alloy of lead and zinc) that nothing but the latter enters the spirals. The spirals themselves in the gun have been subjected to many modifications in number, size, breadth, depth, form, and amount and nature of twist, very often with more ingenuity than knowledge of guiding principles. To discuss these principles here, and within our space, is impracticable. One or two of the main points, however, are these:- Given the calibre, form, and density of the projectile, and its intended initial velocity, a certain velocity of rotation upon its axis of projection, must be impressed to insure accuracy of flight within given limits, and within given limits of range, and at elevations not greatly removed from horizontal. Then, caeteris paribus, that form of rifle grooving will be the best as respects the gun, that shall enable it best to sustain the equivalent of the work that must be impressed upon the shot to produce rotation, with the least amount of cutting away of material, from the interior of the originally cylindrical chase, and chiefly that shall cut least radially, or in depth, from the thickness of the gun. As respects the shot, it is generally true that in proportion as the preceding condition is approached in the form of the gun, so will the form of the shot be good as respects its flight, so far as aerial resistance due to projections from its surface is concerned.