You are here: Home > Firearms > Ammunition

Written by: David Minshall

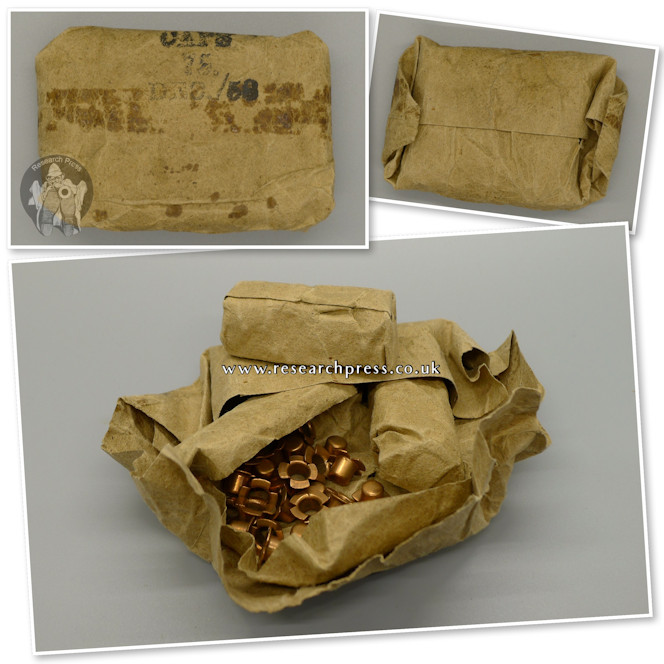

Arthur B. Hawes in his ‘Rifle Ammunition’ (1859) describes the manufacture of the military percussion cap, his notes also including information on packing the finished caps. Scattered across trays, each perforated with 25 holes coinciding with the cylindrical part of the cap, shaking settled the caps in the holes. The 25 caps were emptied into small tin boxes and given to the packer who rolled the caps up into brown paper parcels. Three of these packs were then wrapped into a single parcel of 75 caps, the regulation number served to each soldier with 60 cartridges at the time.

Pictured is an original pack of caps, the wrapper carrying the marking CAPS 75. DEC./58

The three individual packs of 25 can be seen with the outer wrapper.

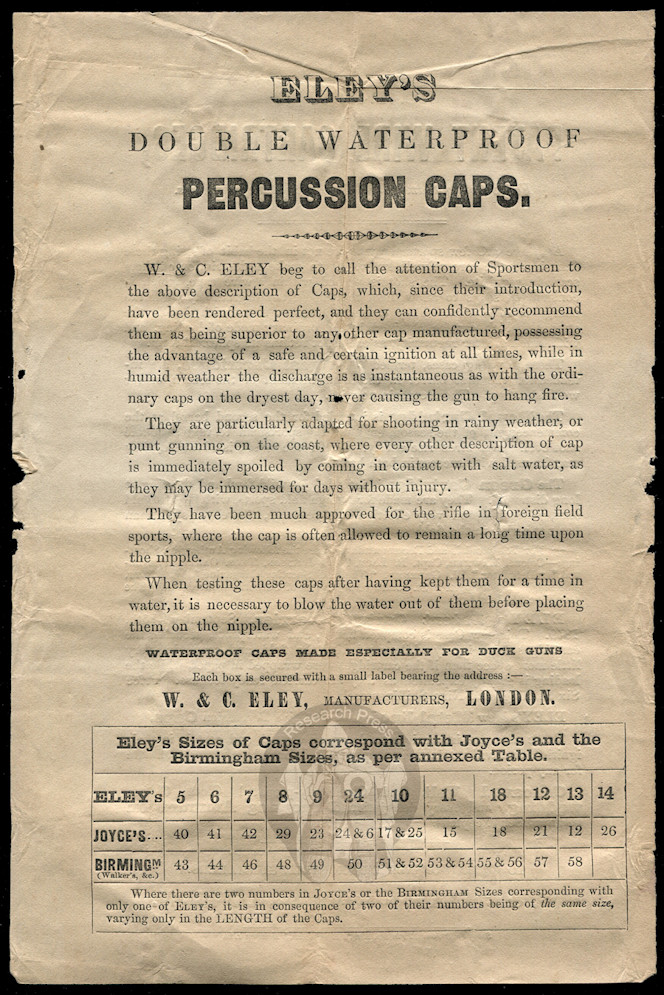

Dr. C.H. Roads noted in his ‘The British Soldier’s Firearm’ (1964) issues with caps in very wet conditions, or of water entering the nipple and permeating into the charge, resulting in hang-fire or misfire. Roads continued, “On the 1st September 1858, at the instigation of the Commander-in-Chief, each soldier was allotted twenty of Eley’s waterproof caps in addition to 75 of the Ordnance variety.” Below is a contemporary Eley advertising leaflet for their “Double Waterproof Percussion Caps.”

William Eley patented his waterproof caps in 1855; they used vulcanized india-rubber (or similar) to protect the detonating primer from moisture. This did not prevent the flash from the cap reaching the nipple.

Note the comparative table of cap sizes from the three main manufacturers shown in the above leaflet – each with their own standards! To assist with the determination of appropriate cap size to fit a particular nipple or gun, manufacturers made gauges available. These were likely used by retailers or salesmen. Illustrated below is an example of a gauge by Eley.

Eley percussion cap gauge, courtesy of C.L. Wilkinson