The Brunswick Rifle: Part 1 > Part 2 > Part 3 > Part 4

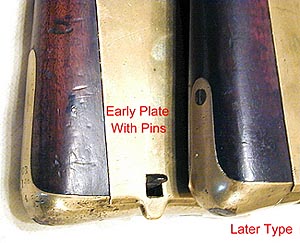

Later the plates were mounted with screws and you will also note a difference in the length of the buttplate tang.

The Buttplate of the early Brunswick had the brass plate fixed to the stock with pins that went through the stock aligning with the mounting brackets of the stock interior.

5Pictured (right) are plates from the second pattern Brunswick rifle and the weapons were dated 1844 and 1847 respectfully.

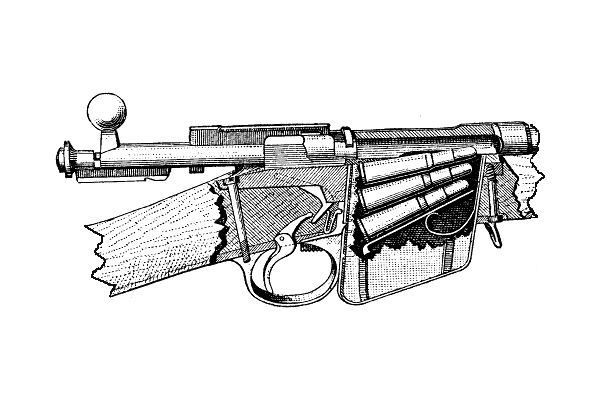

As per example shown in the book:

British Military Firearms 1650 – 1850 (Plate 74, pg.242)

[Hamilton May Collection]

With the pattern of the rifle settled, there came next the question of accessories. Lovell submitted a set of implements in September, but Charles Manton won a minor triumph by getting his Rifle Brigade officers to approve a set of his own design. This consisted of a ball drawer, a brass jag and a combination lever and a pricker. It should be explained that the ramrod had a flat pommel and a hole for the lever at one end, and a brass tip with female thread for the jag at the other. Lovell also introduced the muzzle tampion (stopper) in 1843.

The Brunswick sling was of one piece leather 1 & 3/8 inches wide and 32 inches long. It was tied to the lower swivel by a leather thong. The latter part went throught the upper swivel, came down and fastened to a leather button.

The example here was made to conform to the original pattern by the late Victor Zubatiuk.

The method of carrying these implements and also the linen patches had now to be decided. When Lovell designated the butt box, he apparently intended it for greased patches and a piece of rag for wiping the barrel. In January 1839, however, Maj. Boileau submitted a design for a large rectangular cavity with a turn catch or button to hold the implements, and a smaller round one for the patches or grease. Although Lovell objected, this large trap, six inches long was adopted. The butt box involved two compartments, one to hold loose patches and the other set up to secure a three armed combination tool.

Lovell had brought into production, three entirely new standard weapons, a carbine, a musket, and a rifle. While undertaking a host of other duties, he had been responsible for practically the whole of their design and he was naturally proud of his achievement. Learning that his carbine had been called the Victoria Carbine, but that his musket had been designated Lovell’s Pattern, he wrote, in March 1839, to ask that the rifle might be named “Lovell’s two-grooved Percussion Rifle”, he went on: “I am satisfied that my system is the best yet … My carbine has been named after the Queen, which gallantry and loyalty will not allow me to find fault with – but I should like to have credit for the Musquet and Rifle”. The Master General replied that as the rifle was a modification of one sent by the Duke of Brunswick, it should be called “Lovell’s improved Brunswick Rifle.”

This was hardly a generous action especially as, in 1841 when it was suggested in some quarters that a presentation should be made to Capt. Berners, the Master General then stated that the rifle was developed from the Hanoverian model.

In his endeavors to improve the accuracy of his rifle, Lovell found that, with the normal casting of lead ball and particularly the belted shape, there was a perceptible variance in the weight due to faulty casting, impurities and air bubbles. In October 1837 he proposed that the rifle balls be made by the compressing machine of David Napier, an engineer, which produced a smoother finish and a more solid result. Made in this fashion they weighed 559 grams or 12 ½ to the lb. Extensive tests were carried out between cast and compressed balls and in March 1839 a Committee came to the decision that, while compressed balls made little difference in a musket, there was an advantage to their use with rifles. An agreement was reached to purchase Napier’s machine for 1000 British pounds, subject to twelve months maintenance and a further payment of 500 pounds if satisfactory. The latter was duly authorized on 18th April 1842.

A variant of the infantry rifle was introduced in 1840. When the musket bore was adopted, as standard for all arms, Lovell had to design a new Sergeants musket. He proposed a smoothbore musket for Sergeants of the Line regiments and, for Sergeants of the Guards, a gun with the same barrel as the rifle, which could take a common cartridge. He decided this after reading that the French had adopted rifles for the N.C.O.s. The Musket was similar to the infantry rifle except that it had a 2 ft. 9 in barrel for use with a socket bayonet.

To return to the infantry rifle, two more alterations were to be made. In August 1841, Lovell discarded his back-action lock in favor of a lighter lock with a side action, which could be fitted to all the standard firearms. The new lock was fitted to 4,000 rifles ordered on 31st October 1845. Half of the rifles were made at Enfield and the balance by the London gunmakers.

The London gunmakers, Lacy & Reynolds introduced the last change in October 1847, when they submitted a rifle with an improved spring catch for the sword bayonet. The notch on the bayonet bar was half way along, instead of near the muzzle. Conversly, the release button on the bayonet handle is close to the crossguard instead of being in the middle. This stronger fitting was approved for general adoption by the Commander-in-Chief in June 1848. The Brunswick bayonet was after all a heavy weapon weighing nearly two pounds.