Armstrong Guns > Gun Factory Department > British Service Guns

In Figs. 635 and 636 (below) we present longitudinal sections of the Armstrong 110-pounder, or 7-inch gun, and of the long 12-pounder for hand service – the first really authentic sections of these guns that, we believe, have ever been published. These two may be viewed as types of the whole; all the natures of Armstrong guns admitted into the service, so far, being as follows:

ARMSTRONG BRITISH SERVICE GUNS

| Weights | |||

| Land. Cwts. | Sea. Cwts. | Nature. | |

| 82 | – | 110 pounder | garrison and naval guns. |

| 72.5 | – | 100 pounder | garrison and naval guns. |

| 35.25 | 32.5 | 40 pounder | long and short. |

| 16.5 | 12.5 | 20 pounder | long and short. |

| 8.5 | 8 | 12 pounder | long and short. |

| 6 | – | 9 pounder | same as the 12-pounder, but lighter. |

| 3.25 | – | 6 pounder | |

The short guns are for naval and boat use only. This is, of course, exclusive of such exceptional guns as the 12-ton gun, 10 in. calibre, carrying a spherical shot of 150 lbs., which smashed through the Warrior target at Shoeburyness; or the still larger ones in preparation at Woolwich or Elswick; amongst which is a very large gun making by design of Mr. Lynall Thomas, and of which from the particulars we have learned we cannot predict well.

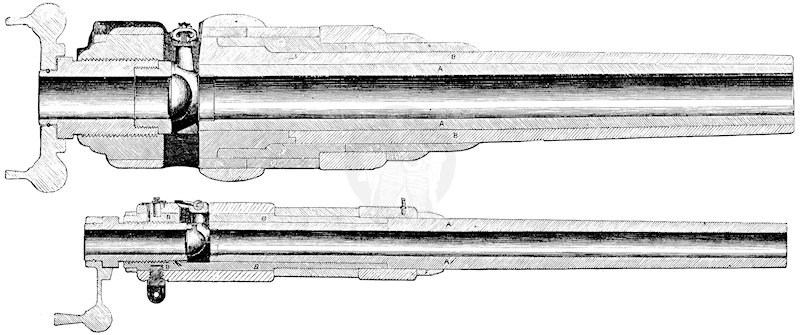

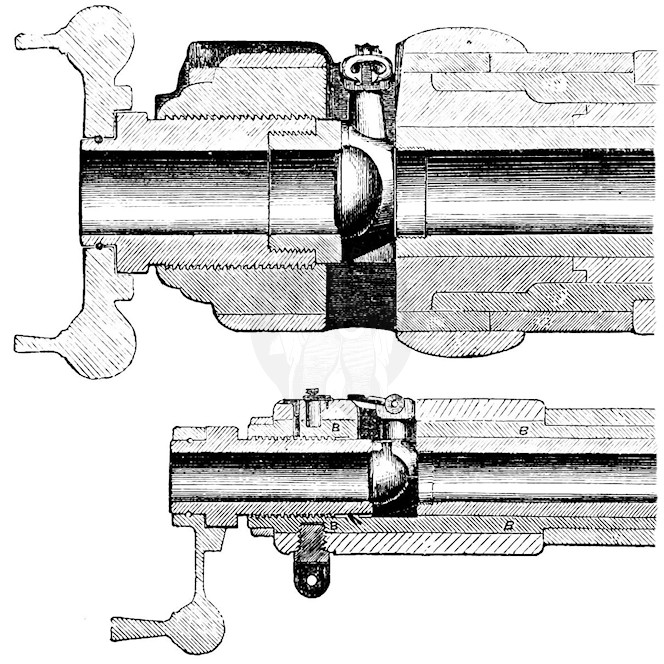

Top: Fig. 635: The Armstrong Garrison and Ship Breech-loading 110-Pounder

Bottom: Fig. 636: The Armstrong Breech-loading 12-Pounder Field-gun

Enlarged detail from Fig. 635 & 636

Referring now to Fig. 635 as illustrative of all others – the breech piece and trunnion ring are the only parts forged solid in the Armstrong gun, and then bored out. In the former the aim is to preserve the fibre of the iron in spiral interlacings approaching the lengthway of the gun, as this piece mainly bears the longitudinal strain of explosion. All the other parts consist of rings longer or shorter, of various forms and sizes, the longest being the two innermost, or tubes, that form the bore of the gun.

The iron of which these rings are formed, is delivered in rolled bars of trapezoidal section, about 30 feet in length each. These are welded up longer, as wanted, sometimes to 120 feet in length; and then, by suitable machinery, this long bar heated red-hot is coiled upon a maundrel (like string round the finger); the edgeway of the bar’s section facing the maundrel, and the wider edge of the trapezoids bar outside. Such coils, suited in diameter and length to their intended uses, are then placed each in an air furnace, and brought to a welding-heat, and struck on end heavy blows, and “patted” (as the affectionate term is) on the sides, under the steam hammer, and so welded into short cylindrical hollow rings. For the long inner tubes several of these are welded together, end to end, without removing them from the air furnace in which they are heated up to the welding-point; by squeezing them end on, suddenly and powerfully, at the right time, by a simple but effective application of large screws, the arrangements of which are also due to Mr. Anderson.

Now the effect of this coiling up and thus welding these cylinders is, that most of the fibre of the bar becomes arranged circumferentially round the future gun, and so in the best way to resist bursting; and it is capable of demonstration, that with iron such as that adopted, and provided it be fibrous, the resisting power of the material of each such ring to the explosive strains, over and above that of the same material forged in a solid block and bored out, is increased in the ratio of about 7 to 1. This increase is altogether irrespective of the strength received by building in successive rings with initial tension.

These rings are now bored and turned, inside and outside, and their dimensions brought precisely to what is required, prior to their mutual adaptation.

Suppose now the inner tube, A, so turned outside, and rough-bored inside, and the next tube, B, that is to go over it, finely bored inside, but of such a diameter that it could not be passed over A, both being cold. The tubes A and B are then placed upright, and a clear-wood fire is kindled below B, which becomes a vertical flue to the fire, is soon heated uniformly to a low red heat. Its diameter has now become expanded, so that it can readily be dropped down over A. It is so dropped and superimposed, and A being kept constantly cool by watering the inside, B is allowed to cool upon it. When cold, B has grasped A with an initial tension, the amount of which is greater, in some proportion, as the internal diameter of B was made less, than the external diameter of A, when both were cold. In principle the same process goes on, with all the rings that go to make up the entire gun. Were iron or any other body in nature perfectly elastic and perfectly hard, and all iron in qualities the same, the theory developed by Dr. Hart would be capable of exactly determining what the difference of diameter should be to produce the required amount of initial tension that, with a given total thickness, and thickness of each elementary ring, should give the nearest approach to perfect equality of bursting strain, throughout the whole of the thickness of the gun. But, as iron exists in nature, all that theory can do, is to give certain leading indications as to the conditions that will give the best amount of initial tension, and those who profess to lay greater stress on any alleged profound applications of theory in practice are here, mere charlatans. We say this having ourselves had the earliest and fullest knowledge of the mathematical theory from its discoverer Dr. Hart, and employed the method upon the very largest scale in the construction of the 36-inch mortars, designed in ringed structure with initial tension, anteriorly to Dr. Hart’s investigations.

The practice at Woolwich is based simply on experience, and wisely so; and we presume it was in allusion to this, that in the discussion of 1860, at the Institution of Civil Engineers, Sir William Armstrong intimated that he attached no importance to any theory of superposition with initial tension – a phrase which appears to have been perversely misconstrued by some of his opponents.

We can scarcely go into any description of the minor details of construction of the Armstrong gun. All the service guns are breech-loaders, with movable vent pieces, held up by the hollow breech screw, through which the cartridge is placed in the gun, and bearing, when in place against a copper ring screwed into the chase.

The minute arrangements of the adjustable sights, and of many other parts, present great perfection and beauty, both of design and execution. Much of this as respects every portion of the manufacture of these guns is, we believe, due to the admirable boring and other tools, and to the complete systematization of process, that have been perfected at Woolwich by Sir William Armstrong, and through the exertions of Mr. Anderson, C.E.

The method of loading at the breech, is an indispensable adjunct of the method of adapting the projectile to the rifled grooves employed by Sir William Armstrong. Breech-loading, however, in whatever way carried out, involves a serious amount of weakening of the gun, at its most vitally important parts, and when the calibre is large involves other serious difficulties and inconveniences. These are such, that his arrangements of breech-loading may be said to have reached, if not surpassed their limits, at the 110-pounder gun, even with moderate charges. This and the demand for still heavier rifled guns, produced the muzzle-loading shunt gun of Sir William – an extremely ingenious device, by the configuration of the duplex rifled groove and ribs of the shot (see Fig. 623), to approximate to what General Sir John F. Burgoyne years ago pronounced to be the legitimate goal for inventions in rifled cannon, viz., “a running shot, muzzle-loading, and so made, that it shall stop all windage, at or immediately after the moment of explosion.” We ourselves still hold that to be the true view, and in so far consider the shunt gun as the most perfect that Sir William Armstrong has yet produced; but it seems to us to have some not unimportant defects. The wear upon the rifled grooves must be very great, and the splitting strain upon the gun (over and above that due to the projectile value of the charge) by the severe compression of the zinc ribs of the shot in expulsion, serious; while the correctness of shooting is far too much dependent upon whether the shot shall centre itself, by an equal and parallel compression of the whole three zinc ribs, or be thrown both out of centre and out of axis, by the greater compression of one of them. As the slightest difference in hardness, &c., of the zinc ribs may determine this result, and absolute uniformity cannot possibly be insured, so the chances against perfect flight in these shot are very great; but the most sustainable points of superiority, in rifled cannon over smooth bores, are accuracy of direction, along with increase of range; if the former be not the most perfect possible, the latter is of greatly diminished value.

Sir William Armstrong patented a new arrangement of “sliding horizontal wedge” for breech-loading (25th March, 1861, No. 743), and this arrangement is, we believe, that exhibited as applied to a heavy gun. We observe, however, that the patent has not been proceeded with; it rather increases the weakening of the gun due to the old plan.