Engineer > Great Exhibition > Firearms > Honours

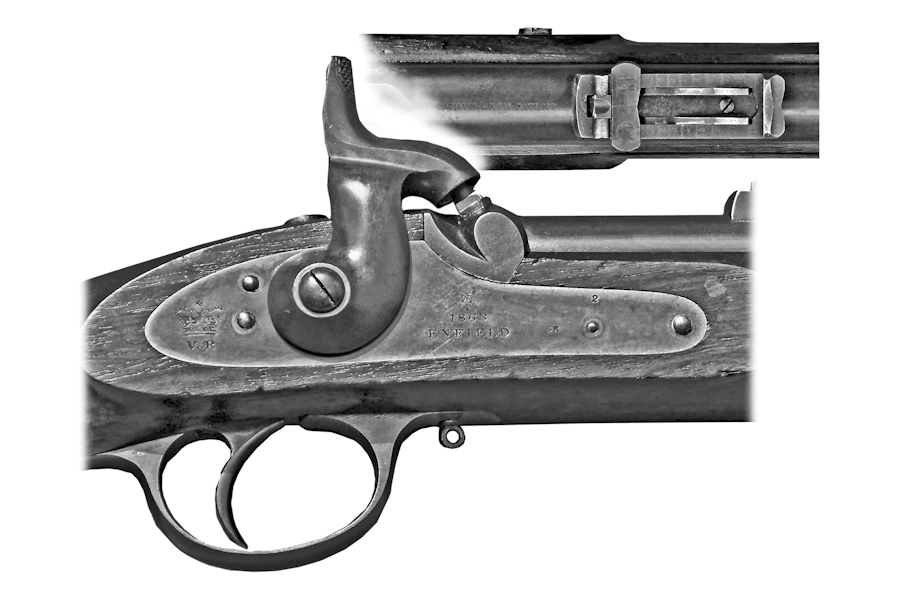

In 1854 Mr. Whitworth was requested by the Government to undertake the construction of machines for the better production of fire-arms, but he declined to do this until he had satisfied himself by experiments what the proper construction of fire-arms themselves should be. With this view, the erection of a large shooting-gallery (in Mr. Whitworth’s private grounds at Rusholme, near Manchester) was commenced in August, 1854, and finished in October of the same year. It was provided with a succession of screens, covered with light tissue-paper, by which the track of a bullet could be traced throughout its whole course. Before, however, its walls had become dried, a large portion of it was blown down during a violent storm, and it was not, therefore, finally completed until March in the following year. On commencing his experiments, Mr. Whitworth was convinced, after careful consideration, that the polygon form was the best for the interior of rifle-barrels and for the projectiles. This form, among other advantages, affords the greatest extent of rifling surface, and enables a mechanical fit to be easily obtained, and rotation is produced without depending upon the expansion of the projectile by the explosion. At the same time, the polygon form, though not dependent on the use of the expansive projectile, is well adapted thereto, in the event of that being considered desirable. When the late Lord Hardinge went to Manchester, accompanied by Colonel Hay, Commandant of the School of Musketry at Hythe, to witness some of Mr. Whitworth’s experiments, rifle projectiles, 3 inches long, were fired with great success from a barrel of the ordinary bore, rifled with one turn in 15 inches. On seeing these results, his lordship was anxious that the principles of construction, which had proved so successful with the rifle musket, should be applied to pieces of ordnance, and at his request three brass 24-pound Howitzers were sent down from Woolwich. These guns Mr. Whitworth bored and rifled hexagonally, the bore being 4 inches in diameter (measured diagonally), 4 inches across the flats, 52 inches long, and weighing 12 cwt. One of the pieces was tried, in Mr. Whitworth’s grounds, at short ranges, both point-blank and at high elevations, with different lengths of projectiles, the results being in every way satisfactory. The first completed rifle made by Mr. Whitworth was fired at Hythe in April, 1857, in the presence of Lord Panmure, the then Secretary of State for War, and his staff. The “figure of merit” (or the average distance of each shot from the centre of the group) obtained at 500 yards range was 4½ inches. General Hay states that no “figure of merit” under 27 inches had previously been obtained with any rifle; and so complete had been Mr. Whitworth’s investigations, and so accurate his calculations, that this” figure of merit” of 4½ inches has never yet been surpassed with any rifle fired in the open air. The Times report of the trial said that it had terminated in establishing beyond all doubt the great and decided superiority of Mr. Whitworth’s invention. “The Enfield rifle,” continued the report, “which was considered so much better than any other, has been completely beaten. In accuracy of fire, in penetration, and in range, its rival excels it to a degree which hardly leaves room for comparison.” In the face of such results, the adoption of the rifle into the service was naturally looked for, and must have followed almost as a matter of course, unless some reason to the contrary had been assigned. Eighteen months passed away without anything being done, and then a Committee of Officers reported to the Government that “the bore of the Whitworth rifle was too small for use as a military arm.” The Whitworth rifle was again brought prominently before the notice of the public and of the authorities at the first Wimbledon Meeting, on July 2nd, 1860, when Her Majesty the Queen opened the proceedings by firing a Whitworth rifle from a mechanical rest. The target was fixed at a distance of 400 yards, and the adjustment was so accurate that the bullet struck within an inch and a quarter of the centre of the bull’s-eye. Two years later, the Ordnance Select Committee published the results of further comparative trials of the Whitworth and Enfield rifles. At 300 yards range, the mean radial deviation of the Enfield was 12.69 inches; of the Whitworth, 3.86 inches. At 500 yards the mean deviations were respectively 19.80 and 7.29 inches; at 800 yards, 41.61 and 15.67; at 1,000 yards, 95.01 and 23.13; at 1,200 yards, 133.53 and 46.92. With regard to the matter of penetration by projectiles fired from heavy ordnance, Mr. Whitworth claimed, so long ago as 1858, that he had proved, by a large number of experiments, that the best form of projectile is one with a flat head, and that such a projectile will pursue a straight course, without deviation, through water, so as to strike a ship far below the waterline, and that it will also penetrate armour-plates which stand obliquely to its line of flight. Shot with rounded heads, when fired downwards into water, rise again by ricochet, and their course cannot be at all foreseen. This fact has been established by firing into a water tank, crossed by screens partially immersed and partially rising above the level of the water, at a target similarly arranged at the other end of the tank. In this year he rifled a 68-pounder cast-iron gun-block on his plan, and with this gun he fired a 68-pound solid shot from the deck of the Stork gunboat, at a range of 450 yards, completely through a 4-inch armour-plate, fixed on the side of H.M.S. Alfred. It should be stated that this was the first instance in which iron armour-plates were completely penetrated. Another great advance in artillery was inaugurated by Mr. Whitworth in 1862, when he fired his patent flat-fronted steel shell through a target representing the side of the Warrior. The weight of the shell was 131 pounds, the bursting-charge of powder 3½ pounds, and it pierced a 4½-inch iron plate, backed up with 18 inches of teak – a performance which at that time was looked upon with wonder. Mr. Whitworth was also the first to demonstrate the possibility of exploding armour-shells without the use of any kind of fuse. Before dismissing the subject of artillery manufacture – a subject with which, it is scarcely necessary to remark, the name of Whitworth is inseparably connected – it will be well to quote an extract from The Anglo-Brazilian Times of April 22nd, 1874. That journal states that “The Committee on Artillery Studies, after nearly two years of consideration of the various systems of cannon, have pronounced definitely in favour of the Whitworth rifle cannon as that which, from its material, the processes of manufacture, and the system, most nearly approaches perfection. The Committee emphatically condemn the French system of cast-iron strengthened by wrought-iron bands as unscientific, and practically proved inefficient. The Krupp gun, of Krupp cast-steel, strengthened with bands, they consider unreliable, notwithstanding its fine material, chiefly owing to the uncertainty and irregularity of effect which, they say, always attend the action of the hammer, however ponderous, on masses of iron. Finally, they consider the English Armstrong, Woolwich, and Whitworth cannon much superior, in construction and strength, to the best yet produced on the Continent: the Woolwich an improvement on the Armstrong, and the Whitworth far ahead of either in the essential qualities of a good gun. This superiority of the Whitworth cannon the Committee ascribe to the quality of the homogeneous steel used, to the care in its selection, to the oil tempering which it receives, to the use of the hydraulic press instead of the hammer, and to the mode of constructing and connecting the cylinders and other parts of the gun. In relation to the quality of duration, the Committee mention that, while the Krupp cannon has an average life of 600 to 800 shots, the Whitworth cannon employed by the Brazilian forces during the Paraguayan war have averaged 3,500 to 4,000 shots each, without a single case of bursting or serious damage having occurred among them.” It should further be mentioned that Mr. Whitworth has always contended that guns should be made of steel; and in the course of experiments he found that by subjecting the metal to extreme pressure when in a fluid state he could produce steel of absolute soundness. He rejects as unsuitable, in the manufacture of guns, the combination of a weak and a strong metal, such as iron and steel. In a book written by him –” Guns and Steel,” published in 1873 – he enters fully into this matter, and explains his plan for subjecting the fluid-casting to enormous hydraulic pressure, by which all the air is forced out; and in this way obtains a ductile steel that is perfectly solid and homogeneous, and that resists the action of explosive forces in a greater degree than any other form of metal. He maintains that it is possible to make guns of ductile steel possessing twice the strength of iron, and completely master of the gunpowder. The Whitworth breechloading gun, made of fluid-compressed steel, with its large powder-chamber, cannot, it is said, burst or break up into pieces. For penetrative and destructive power it is designed to fire shell of such length and capacity as no one would venture to use for a gun of mixed iron and steel; while its range will be, at high elevations, from forty-five to fifty per cent. greater than that of a muzzleloading service-gun of the same calibre.