Introduction > Comparative Trials > Hythe Trials > Woolwich Trials > Rifle Fired by the Queen > Ordnance Select Committee > Henry & Metford Rifles > Hexagonal Rifling

First Comparative Trials Of The Whitworth And Enfield Rifles

In the year 1855 I commenced a series of experiments in the new rifle gallery, and was at that time requested to adhere to the service charge of powder, viz., 70 grains, as well as to the service weight of bullet, viz., 530 grains, but I was unrestricted in every other particular.

The barrel of the Enfield rifle, as then used in the service, was 39 inches in length, its bore being .577 of an inch in diameter. The rifling was effected by three spiral grooves, making 1 turn in 78 inches, and the bullet rotated half a turn during its passage along the barrel. The length of the bullet was 1.81 diameters of the bore.

The bullet was cylindro-conoidal; it was wrapped in paper, and was made of such a size as to pass easily down the barrel, and had a conical wood plug in its hollow base. At the instant of firing, the explosive force of the powder caused the bullet to become expanded or upset, and thus moulded it to fit the grooves in the bore. It was essential that the lead should be very pure and soft in order to allow of its being properly expanded into the grooves.

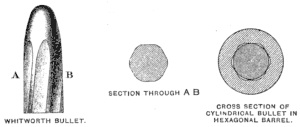

The bullet is shown in the diagram.

The cross section of the barrel is given at D, the circular portions, which do no work in rotating the bullet, are called lands, and the grooves run in a screw thread of uniform pitch between the lands.

The barrel of the Whitworth rifle is 39 inches in length, the interior is hexagonal in section, and, instead of consisting partly of non-effective lands and partly of grooves, has rifling surfaces which are wholly effective. The rifling turn is much quicker than that of the Enfield rifle, being 1 turn in 20 inches, and the angular corners of the hexagon are rounded in the manner shown. The maximum diameter of the bore is .490 of an inch, and the minimum diameter is .451 of an inch.

The bullet may be either hexagonal or cylindrical; in the latter case, it will expand and be driven into the recesses of the hexagon, and will adapt itself to the curves of the spiral rifling; in the former case the inclined sides of the hexagon offer no direct resistance to this expansion, which is easily effected. The length of the bullet is 3 diameters of the bore.

With all expanding bullets, a quick burning powder must be employed. The expansion depends on the sudden action of the powder upon a bullet possessing inertia, it therefore fails with a slow burning powder.

If there be a mechanical fit between the bullet and the bore of a muzzle-loading rifle, this expansion is no longer necessary, and the bullet may then be made of alloys of tin and lead of any degree of hardness, or a hardened steel bullet may be used. It is perfectly easy to form a mechanically-fitting bullet adapted to the hexagonal rifling, on account of the simplicity of the form, but quite impracticable to obtain an accurate fit between the bullet and the bore of the rifle where any system of grooves is adopted.

The expansion principle may be combined with an easy mechanical fit, so that a projectile made of metal harder than lead, such as an alloy of lead and tin, may be used, and the bullet will then expand sufficiently to fill the bore, giving a penetration more than double that of lead.

In my earlier experiments I tried the effect of lengthening the bullet of the Enfield rifle, and I showed, by means of a piece of tissue paper placed three yards from the gun, that an increase of only a quarter of an inch in length caused the bullet to strike obliquely. This fact was clearly ascertained by the mark left upon the paper. I then made a barrel of the same bore with a twist of 1 turn in 30 inches, instead of 1 turn in 78 inches, and I kept the weight of the lengthened bullet at 530 grains by making a portion of the interior hollow. The result was that with the same charge the bullet hit the target at the same height.

Having thus proved that there was no loss of range on account of the increased rotation of the bullet, and that the trajectory was as good as before, I made another barrel, reducing the minimum diameter to .5 inch, and lengthening the projectile, and finally I reduced the bore to .45 inch.

In order to satisfy myself as to the effect of increased twist in the rifling I tried barrels with 1 turn in 20 inches, 1 turn in 10 inches, 1 turn in 5 inches and lastly with 1 turn in 1 inch. I fired from these barrels mechanically fitting bullets of lead and tin, and with the barrel rifled to 1 turn in 1 inch (using 35 grains of powder) I penetrated through 7 inches of elm-tree planks.

In this way I exhausted the subject, and arrived at the result that the best twist for a rifled musket bullet would be 1 turn in 20 inches, the minimum diameter of the barrel being .45 inches.

This construction gave the best shooting with the charge of powder and weight of bullet to which I was limited.

If the ordinary strength of a man was greater than it is, the Enfield bore would be right but it would be necessary to increase the length of bullet and the twist of rifling, the rifle itself being also made heavier in proportion.

I experienced great opposition to the change of rifle turn from 1 turn in 78 inches to 1 turn in 20 inches, or I should have made the twist somewhat more rapid in order to fire a steel bullet when necessary for penetration. It should be understood that the amount of rotation must be increased when the specific gravity of the bullet is made less, otherwise the projectile will fall over in its flight, – that is to say, an iron projectile requires more rotation than one made of lead.

The same principles apply in determining the rotation for the heaviest guns. A long projectile turns over unless it has sufficient rotation, and the twist for field guns should not be less than 1 turn in 15 diameters. The gun will then fire projectiles 6 diameters in length.

I have always contended that the primary element of success in long range shooting, is length of bullet, and generally that great range, with a low trajectory, accuracy and penetration are obtained by employing a long bullet, high rotation, and a large powder charge.

The superiority of the Whitworth, as compared with the Enfield rifle, was first proved in a series of trials made at Hythe, in the year 1857, under the direction of Lord Panmure, then Minister of War.

These trials led to no satisfactory conclusion, and after a lapse of eighteen months a Committee of Officers reported to the Government in 1859 that the bore of my rifle was to small for use as a military weapon.

Compare with this the report of another Committee of Officers made in 1862, “that the makers of every small-bore rifle, having any pretensions to special accuracy, have copied to the letter the three main elements of success adopted by Mr. Whitworth, viz., diameter of bore, degree of spiral, and large proportion of rifling surface.”

In 1869 a Special Committee reported to the War Office that the calibre of a breech-loading rifle, should be .45 inches, as appearing to be the most suitable for a military arm. This conclusion is directly contrary to that arrived at in 1859, but is the exact bore which I recommended in 1857.

The mechanical question is the same whether we deal with a rifled musket or the heaviest gun. I have from the commencement advocated one uniform system, the value of which I have established by direct experiment.

As regards heavy artillery, it will probably require some long interval before the professional advisers will be enabled to see that sound ductile steel is the best material for a gun, that the bore for a given weight of gun should be made smaller than that used in the service, that the projectile should be lengthened, that its rotation should be increased, and that the stud system should be abolished.

In this direction they have made one step. They have taken the weight I proposed for a gun of 12 inches bore, and have increased the weight of the service 12 inch gun from 25 to 35 tons. In all other respects the Woolwich system is in direct opposition to my own. Following past precedent it must be expected that when the truths I have endeavoured to press upon official attention are fully understood, and action is taken upon them, my part in first developing them will probably be forgotten.